We designed, bult and tested 2 new RCT0056 RF Receiver Simulators. These simulators match the performance of an RF system front end (noise figure, gain, Pin1dB, slope), and when connected to the back end of the system, the full system can be tested without the need for actual front end hardware. 12 Frequency bands were provided, from VLF up to mmW frequencies. Adjustable attenuators with front panel controls were added to allow gain adjustment during testing.

We designed and built a complete low cost RF/Microwave Test Station capable of providing signals and measuring responses from 10 MHz to 18 GHz. The station also provides Digital I/O and measures analog voltages. This test station is shown testing RF to Fiber Optic transmitters and Fiber Optic to RF receivers, testing and evaluating the complete RF fiber optic loop. Everything is controlled by a USB interface. When coupled with our Automated Test Software, this station can perform many RF measurements, including gain, Pin/Pout 1dB, isolation, relative attenuation, and more. Everything is enclosed in a 3U chassis.

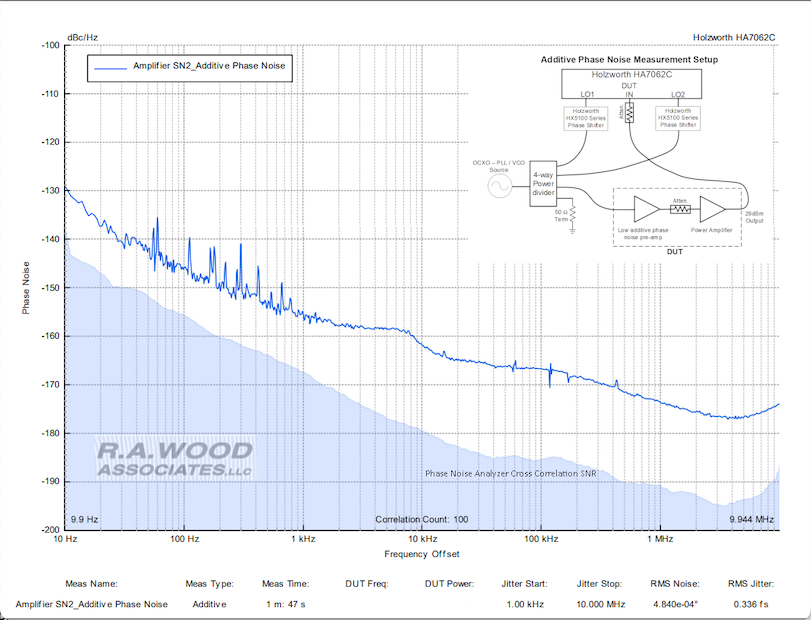

We've recently designed, built, and tested a 6U VPX microwave module for a high performance radar system with state of the art residual phase noise performance. The module was tested with our Holzworth Phase Noise Analyzer. Residual phase noise of <-155 dBc/Hz at 1 KHz offset and <-162 dBc/Hz at 10 KHz offset were acheived. Spurious levels were <-130 dBc. Internal detectors provided input and output detected power levels for Built-in-Test reporting. This module was tested using our in-house vibration, temperature, and shock qualification equipment.

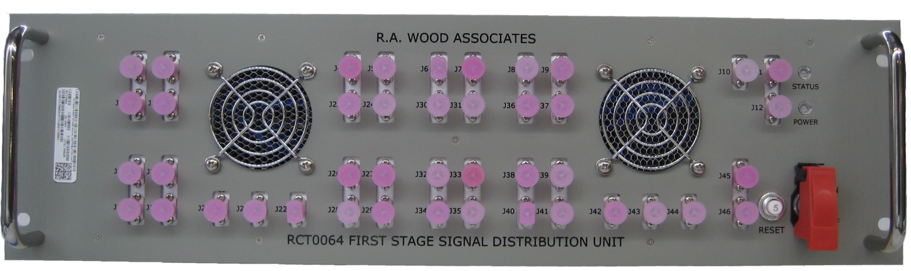

We've just designed and delivered a new product: First Stage Signal Distribution Unit (FSSDU). This 3U unit provides many functions, including:

- Amplification and equalization of extremely wide RF and Microwave frequency bands

- Distibution of bands to support many receivers and carry-on equipment

- Combining of frequency bands to create a broad spectrum output for wideband analysis

- Low noise figure, high dynamic range amplification to maintain the system RF signal path performance

- This unit replaces an older unit with new hardware and expanded capability

- Ethernet Interface

We've recently designed and delivered a new 1U Height BIT (Built-in-Test) / DVA (Digital Variable Attenuators) Assembly. This unit provides:

- Wide Microwave Frequency Band coverage across 8 inputs

- The capability to inject BIT Signals into each microwave input to support system health testing and grooming

- Gain Adjust and high dynamic range Amplification using our RCT0061 Wide-Band Digital Attenuator Amplifier

- Equalization to correct negative slope across the frequency band

- Creation of mmW BIT signals using frequency doublers

- Ethernet Interface

This part can be used anywhere in a system to inject Built in Test signals, while still maintaining the RF path dynamic range and noise figure. It's small 1U height allows it to fit in many locations in a system.

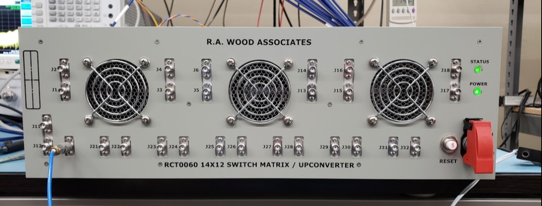

We just delivered our 1st 14 X 12 Microwave Switch Matrix / Up Converter (RCT0060). This unit allows 14 microwave inputs to be switched to any of 12 Microwave outputs. This was an extremely challenging design, with custom designed 12-Way power dividers, our own RCT0050 WB Amplifiers, custom designed SP2T Switches, and custom designed WB Digital Attenuator/Amplifiers. The whole unit is made to fit in a 3U rack mount location. Congrats to our great mechanical and electrical design, and integration and test team for developing this successful design!

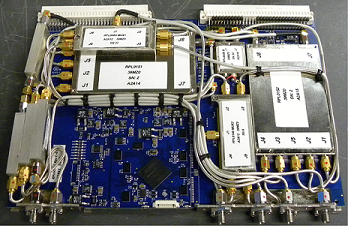

We designed and built an RF Receiver Sumiulator RCT0053, designed to simulate the front end characteristics of an EW system, from the antennas to the downstream rack equipment. We used our customer designed RCT0050 WB amplifiers in many of the 6 microwave channels.

Hi Everybody

We've recently developed the capability to automatically measure surface mount capacitors and bin them into very tight tolerance windows. We can work with 0603, 0402, and 0201 size capacitors. We can provide down to 2-2.5% tolerance capacitors for values down to 0.1 pF. These parts are typically only available in very wide tolerances (up to 50%).

This capability is very useful for filter designs, and other microwave circuit designs.

These tight tolerance capacitors can reduce or eliminate tuning typically needed to meet performance requirements.

We are going to start providing these parts to customers on a trial basis. If you are interested, please contact us to see how we can help you out!

We delivered a new design to one of our customers: An 8X8 Microwave Switch Matrix /Up Converter. The unit allows 8 RF/microwave inputs to be routed to any of 8 RF/microwave output ports. The design includes:

- Custom designed 8-way power dividers (covering a 4:1 bandwidth)

- A low band Up Converter

- An AC/DC power supply

- High Speed LVDS interface

- High Dynamic Range RF amplifiers on inputs and outputs

- Custom designed equalizers for slope correction, and

- FPGA board for control and status (Built in Test) monitoring

The entire assembly is housed in a 2U rack mount assembly, saving precious rack space. The full frequency coverage is 0.5 to 18 GHz.

The RF Switch/DIO Box is a custom designed LRU that provides:

- Automated RF Switching to 1 of 6 RF Inputs and 1 of 6 RF Outputs up to 18 GHz

- Oscillators needed for Test Units

- Digital I/O to control and read digital signals to/from Test Units

- Relay Switching to read Resistances and switch DC Power to Test Units

- Bench top or Rack mount

We have built 5 of these for our own automated test stations. The design is universal and can be used for multiple test applications.

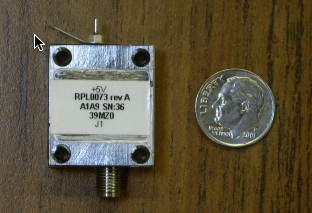

We have officially released a new line of SimpleCycle crystal oscillators. These are temperature compenstated crystal osciillators in a very small package with +5 Volt DC in, and an SMA output connector. The key features include:

- Small package size: 1.06" X 0.92" X 0.37"

- 4 through-holes for mounting

- Easy connections: +5V DC in, SMA out

- Custom frequencies available from 40 MHz to 1.4 GHz

- Frequency accuracy at +25C: < +/-1 ppm

- Internally temperature compensated: < +/-1 ppm from -20C to +70C

- Aging: < +/-3 ppm first year, < +/-1 ppm/year thereafter

- Sine wave outputs (initially)

We will be working to supply these with very quick turnarounds. For more information see our SimpleCycle Oscillator page, or contact us.

We haven't posted in a while. It's because we've been crazy busy. Our newest product, the RCT0017 WB Tuner and Quad Converter, has been under development over the past 2 years, and is now available. We've designed this from the ground up to meet state of the art high input compression point, low phase noise, fast tuning speed, wide dynamic range, and wide instantaneous bandwidth requirements. A quick overview of the specifications:

- Frequency Coverage: 2-18 GHz

- First IF’s: 2.2-3.8 GHz, 3.8-5.3 GHz, available simultaneously

- Second IF’s: 4 outputs at 750 MHz, 375 MHz wide, providing 1.5 GHz instantaneous bandwidth across the First IF’s

- Input 1 dB Compression Point: >+6 dBm

- Noise Figure: 21 dB

- Input Dynamic Range: -60 to +2 dBm

- Gain: 10 dB average

- Tuning Speed: <1 uSec

- Frequency Step Size: 375 MHz

- Phase Noise: -150 dBc/Hz @ 10-20 MHz Offset

- Form Factor: VME 6U 2 Slot Design

- Control and Status: VME A24 D32

- Designed to follow an Low Noise Front End with Approximately 30 dB ENR

- Designed to drive 1 GHz Digitizers linearly up to +12 dBm

A brief data sheet can be downloaded from this link

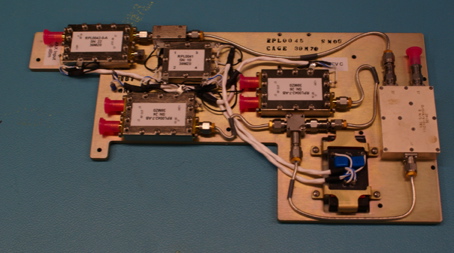

We designed and built for production a 4 channel Quad Converter. Our Quad Converter design features:

- 2 Input IF's from 2.2-5.3 GHz, available simultaneously

- Output IF's: 4 outputs at 750 MHz, 375 MHz wide, providing 1.5 GHz instantaneous bandwidth across the input IF's

- Control and Status: VME Interface A24 D32 and UART Serial Interface

- Designed to drive 4 1 GHz Digitizers linearly up to +12dBm

- 5 custom surface mount RF assemblies mounted to an aluminum plate

- Separate multilayer circuit board accommodates power conditioning, FPGA signals and VME interfacing

- Form Factor: VME 6U 1 Slot Design

- RF Connector Interface: SMA

This is a very complex design with very high density surface mount assemblies. Surface mount assemblies are built using pick and place machines at a contract manufacturer. Automated RF test rack, fixtures and software has been designed at R. A. Wood Associates.

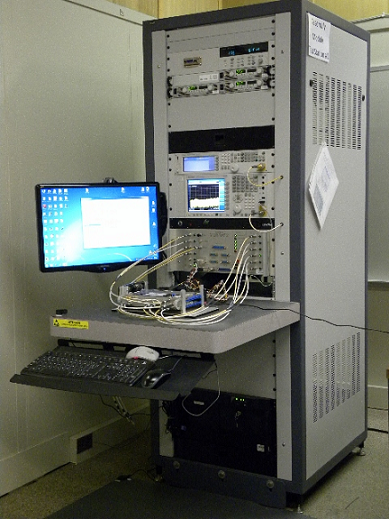

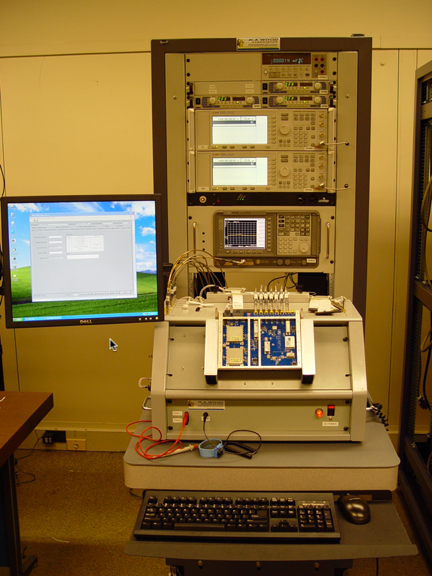

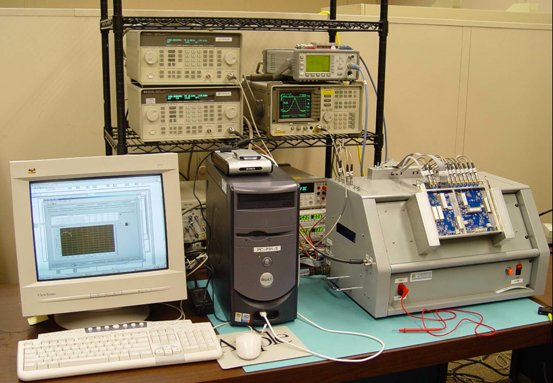

An automated RF/Microwave Test Station was designed and built by R. A. Wood Associates. The purpose was to provide automated test and device characterization to:

- Reduce manual test time

- Eliminate errors in recording of results

- Increase throughput

- Eliminate manual RF connections and DC connections in mid-test

- Provide automated test reports

- Save test results electronically in a database structure

This automated test station reduced product test time from 24 hours of semi-automated testing down to approximately 2 hours. The RCT0017 Automated RF/Microwave Test Station includes:

- DAQ/Switch Unit

- Three programmable power supplies

- Signal Generator

- Spectrum Analyzer

- Custom RF Switch/DIO Box

- Table/Work Surface

- Rack Mount Computer

- Monitor

- LabVIEW Software utilities to support setting up the Spectrum Analyzer and Signal Generator, retrieving data from the Spectrum Analyzer, controlling the RF Switch/DIO Box and other measurement equipment in the Test Station

- Storage drawer

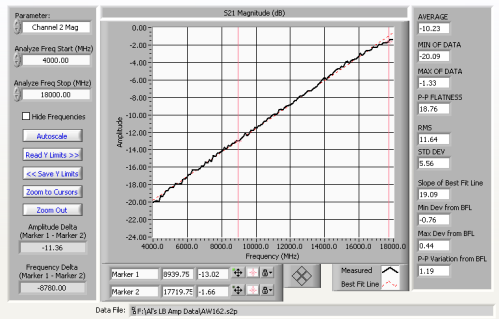

A LB RF Receiver Simulator was designed to simulate the RF front end of a submarine periscope subsystem. The noise figure, gains, and dynamic ranges were designed to simulate the actual subsystem. The amplifiers were custom designed and equalized by R. A. Wood Associates to cover a wide bandwidth from ~DC to 3 GHz. A variable attenuator allowed the output noise floor to be adjusted in 1 dB steps.

We designed and built a 2nd (different) Automated RF Test Station for NAVSEA NSWC, which was delivered to Crane, Indiana. This Test Station contains many state of the art features and equipment, including:

- Tektronix RSA6120A Real Time Spectrum Analyzer

- An R. A. Wood Associates custom designed Test Set Load Box, capable of handling 50W loads

- Rack mount computer, keyboard, and monitor with digital I/O, GPIB interfaces

- A PXI chassis with fiber optic interface, digital I/O, serial interfaces, temperature monitors, and GPIB interface

- LabVIEW Software utilities to support setting up the Real Time Spectrum Analyzer, retrieving information from the Real Time Spectrum Analyzer, controlling the Test Set Load Box, and controlling other measurement equipment in the Test Station

The customer wanted this delivered before the holiday, so we rented a delivery truck and spent several days driving it out and setting it up for the customer at their facility. They were very pleased with our commitment to deliver the station on time!

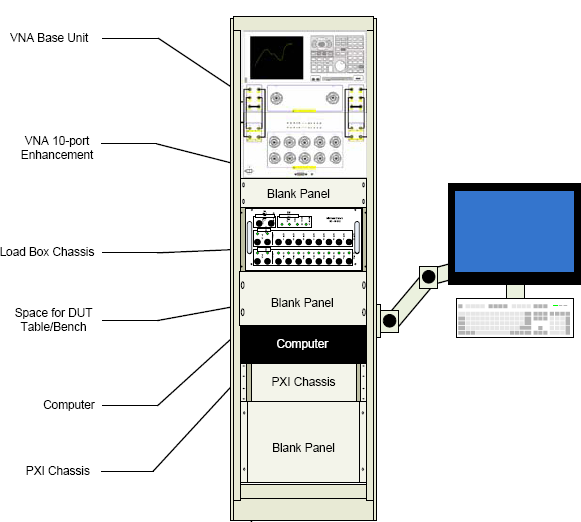

We delivered a Test Station to NAVSEA Naval Surface Warfare Center (NSWC) in Crane, Indiana. The Test Station contains many state of the art features, including:

- The latest Agilent Network Analyzer (PNA-X Series)

- A 10-port Extension for measuring multi-port S-parameters

- An R. A. Wood Associates custom-designed RF Load Box/Chassis for testing high power RF devices

- Rack mount computer, keyboard, and monitor with digital I/O, GPIB interfaces

- A PXI chassis with fiber optic interface, digital I/O, serial interfaces, temperature monitors, and GPIB interfaces

- LabVIEW Software utilities to support setting up the Network Analyzer, retrieving S-parameters from the Network Analyzer, controlling the RF Load Box, and controlling other measurement equipment in the Test Station

This was a very exciting project, and we really enjoyed working with our customer on this program. The complete project was delivered within 7 months of the order being placed. Great job everybody!

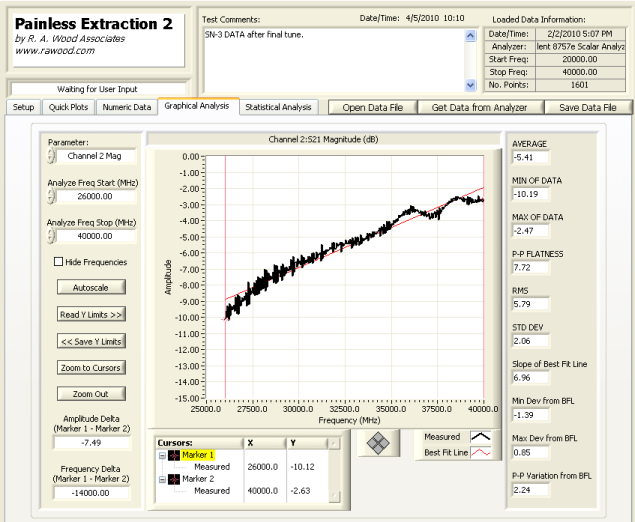

One of our customers had a need for a mmW equalizer to help offset a 7 dB negative slope across a 26.0 to 40.0 GHz band. We looked far and wide to see if there were any available components out there in the industry that we could buy as an off-the-shelf part, or have someone develop for us.

We could not find any available parts. So we took on the task ourselves to design a mmW equalizer with a 7 dB positive gain slope. This is just another example of how we can break new ground to come up with designs that are needed by our customers when they are not otherwise available.

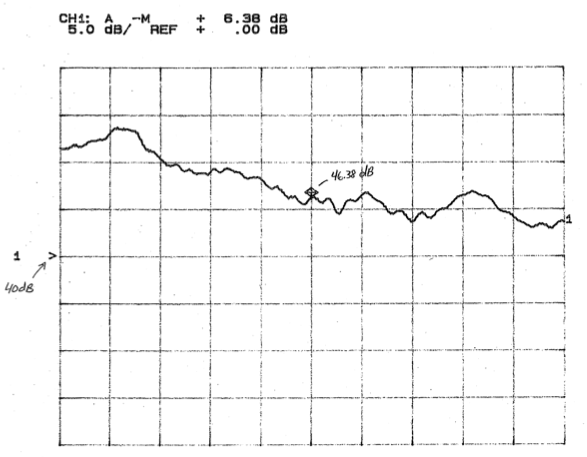

The equalizer was installed in the system, and the 7 dB negative slope was flattened out. See before and after pictures below. Another exciting success story!

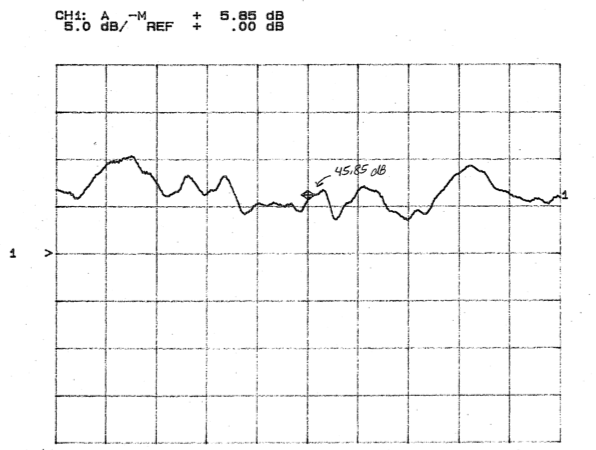

System RF Path Gain before equalization (26-40 GHz):

System RF Path Gain after equalization (26-40 GHz):

We've delivered the third Electronics Support Switching Uint (ESSU) for one of our customers (ahead of schedule!). This was another set of hardware slated to to be installed on a Navy Vessel. The ESSU is shown here with the cover removed, looking from the back. All RF components are mounted on both sides of a center RF plate. Shown are RF amplfiers, equalizers, attenuators, RF switches, cabling, FPGA card, and rear connectors (21 RF connectors, 12 video/75 ohm connectors, Audio, Power).

For additional information, please visit our ESSU information page.

R. A. Wood Associates has been awarded a contract from Naval Surface Warfare Center (NSWC), Crane Division. The contract involves designing and delivering an automated test rack consisting of:

- A 40U rack with rack mount PC, work table, LCD monitor, GPIB controller cards,

- A state of the art Vector Network Analyzer (VNA) with 10 port extension

- A PXI chassis with PXI cards providing thermocouple temperature measurement, serial ports, 2 X 96 digital I/O signals

- A custom designed RF Load Box for testing up to eight transmitter/receiver modules, capable of providing 50 Watts of RF power

- Custom designed software for controlling the Load Box and the VNA equipment

We are fortunate to be able to work with Viewpoint Systems on this contract.

This contract was won on a competitive bid, and our solution was selected out of many other submissions. We are very excited about the opportunity to work with NSWC Crane Division!

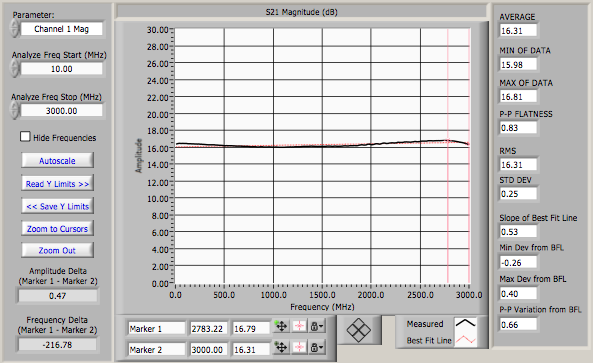

We've extended the frequency range of our extreme BW RF Amplifier from 5 KHz to the upper end of 3 GHz. We customized the input equalizer to create a very flat gain response across the entire band. This amplfier was used for a direct laser modulation application. The measured performance was:

- Average Gain: 16.31 dB

- Slope: 0.53 dB

- P-P Flatness: 0.83 dB

- Min Gain(Low Freq): 15.30 dB

- Max Input Return Loss: -13.02 dB

- Max Output Return Loss: -9.99 dB

- Average 1 dB Output Comp Point: 20.7 dBm

- Min 1dB Output Comp Point: 19.97 dBm

- Noise Figure at Low Freq: ~12.8 dB

- Noise Figure at High Freq: ~ 5.77 dB

More information is available from our Extreme BW RF Amplifier page. Let us know if you are interested in this product line! Bob Wood.

We've delivered another RF Receiver simulator to one of our customers. This unit simulates the RF front end characterisitcs (noise figure, gain, dynamic range) of an EW system, so the customer can connect it to their back end system and validate full system end to end performance (system sensitivity, etc), without requiring the expensive front end components. Frequency coverage goes from 10 MHz to 40 GHz on this unit.

If you have a need for one of these types of products, please contact us.

We've been very busy this past year. Over the last 8 months, our super qualified staff have accomplished the following:

- Developed automated test software for a complex RF/digital board providing RF receive, transmit, and digital signal processing functions

- Modified/retrofitted 12 automated test stations to test this complex RF/digital board

- Developed automated test software to test a LRU chassis, including point to point wiring and DC power supply checks

- Modified/retrofitted 2 automated test stations to test the LRU chassis

- Developed automated test software for a high frequency radar receiver/transmitter board, including a waveguide interface

- Modified/retrofitted 1 automated test station to test the high frequency radar receiver/transmitter board

- Developed automated test software for an IF frequency radar receiver/transmitter board

- Modified/retrofitted 1 automated test station to test the IF frequency radar receiver/transmitter board

How can we help your company improve your manufacturing efficiencies with automated test stations and software?

Using our Extreme BW RF amplifiers, we designed, built, and tested 7 LB RF amplifier modules for one of our customers. Our customer's original vendor failed to deliver their amplifier products and meet the requirements. So we stepped in and helped them meet their delivery schedules. These modules were made to "drop in" to our customer's modules.

These modules will be used in our customer's systems, which will be installed on board Navy vessels.

A full set of test data was provided for each LB RF Amplifier Module delivered. Our automated RF test software (RFSpecTest and Painless Extraction) helped to quickly capture the test results and create the test reports.

Another great effort resulting in a great potential product!

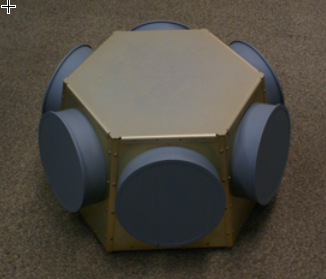

R. A. Wood Associates designed and built a Direction Finding (DF) Antenna Assembly for one of our customers. The Assembly was designed, built, tested, and delivered in less than 6 months. The requirement was to develop an antenna assembly that could be used as a front end in front of a pair of COTS (Commercial Off the Shelf) receiver boards. The DF Antenna Assembly provided the capability to supply Direction Finding (DF) for incoming signals or emitters. The DF Antenna Assembly included:

- Capability to provide amplitude and phase DF between antenna pairs

- 360 degree angular coverage

- Low cost universal design (can be used with many different receivers)

- Low noise figure RF front end (~3.5-4.0 dB)

- Calibration injection to calibrate receiver amplitude and phase

- Wide frequency coverage (500 MHz to 3 GHz)

- High dynamic range

- Digital Compass for DF Antenna Assembly pointing information

- RF switches controlled by an Ethernet interface

More information is available from our DF Antenna Assembly www page

Hello Everybody

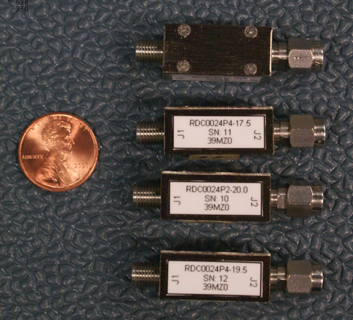

We've enhanced our portfolio of equalizer designs with new high frequency equalizers, with low losses all the way up to 18 GHz!

We also now have a smaller package design (M02 package).

We can now offer low loss, high linearity equalizers over the following frequency bands:

- 5 KHz to 2.0 GHz

- 0.5 to 8.0 GHz

- 1.0 to 8.0 GHz

- 1.0 to 2.0 GHz

- 2.0 to 4.0 GHz

- 4.0 to 8.0 GHz

- 4.5 to 12.5 GHz

- 4.0 to 18.0 GHz

- 8.0 to 18.0 GHz

For more detailed information on available designs, including measured S21 ans S11 plots, and package outlines, visit our "Equalizers on Demand" product page.

R. A. Wood Associates designed, built, tested, and delivered 2 Electronics Support Switching Units (ESSU) to one of our customers. This was another set of hardware slated to to be installed on a Navy Vessel. The ESSU was designed to be installed between the front end (Antennas, RF amplification switching, filtering) and back end (RF processing) of a complex RF/Microwave system. The purpose of the ESSU was to allow a second front end (RF Subsystem 2) to be switched into the same back end, to make use of the RF signal processing in the back end.

Some of the major components in the ESSU are as follows:

- Wideband RF/Microwave amplifiers

- Our Extreme BW RF amplifier was used in this design for the low frequency, wide bandwidth RF path

- Equalizers and attenuators to align the RF paths

- Some vendor purchased equalizers were used

- R. A. Wood Associates equalizers were also used where vendor equalizers were not available

- Terminated mechanical RF switches (50 ohms)

- Terminated mechanical RF switches (75 ohms)

- HDRFI external RF interface to save RF connector space

- DC power conditioning

- FPGA card to control switches and provide Built-in-test (BIT) status

- LED displays for BIT and switching status

- Custom designed audio switching board

We've taken a challenge and come out on top again! We've developed an Extreme BW RF Amplifier, providing ~22 dB gain, and high dynamic range (~36 dBm Third Order Output Intercept Point) over the frequency band of 5 KHz to 2 GHz. An integrated RF package of 1.9" L X 1.3" W X 0.4" H was developed for the Extreme BW RF Amplifier and also included:

- DC filter to suppress power supply ripple and noise

- An input Equalizer where you can specify the full band slope desired

- An output Resistive Power Divider for providing 2 equal RF outputs

The input Equalizer and output Power Divider can be "zeroed out" if not needed. The input Equalizer can be used to compensate for the amplifier slope and/or passive loss slopes. We can provide a variety of RF slopes in the input Equalizer. More information is available from our Extreme BW RF Amplifier page. Let us know if you are interested in this product line! Bob Wood.

R. A. Wood Associates designed, built and tested and delivered 2 "JBU RF PLate" Assemblies. These RF assemblies were used to provide wideband gain, equalization, and Built-in-test (BIT) injection between two very long RF cable runs (between an Antenna Assembly and below decks receivers). The gain and equalization was needed to preserve the RF path noise figure and dynamic range performance through the long cable run.

The exciting part for us is that this design will actually be deployed on a US Naval vessel. This is our first of several LRU's that were designed to be used on a US Naval vessel.

New "Equalizers on Demand" RF products available

Greetings! We've been very busy working on creating a new series of RF/microwave products: "Equalizers on Demand". "Equalizers on Demand" are wideband, low loss frequency equalizers made to provide a positive gain slope from the lower frequency to the upper frequency. These equalizers are designed to flatten out slope caused by long cables or other passive losses, or amplifier negative gain slopes. We have developed a wide series of equalizers with various slopes covering the following frequency bands:

- 5 KHz to 2.0 GHz

- 0.5 to 8.0 GHz

- 1.0 to 8.0 GHz

- 1.0 to 2.0 GHz

- 2.0 to 4.0 GHz

- 4.0 to 8.0 GHz

- 4.5 to 12.5 GHz

Equalizers are very important to help your system obtain the best dynamic range performance. You can use them to flatten out a negative gain slope to reduce gain tolerances/differences before going into high dynamic range amplifiers.

We're hoping this series of products create a new paradigm in RF performance. We can provide these very quickly to help correct slope in an RF path, "Equalizers on Demand" can trim RF path slopes almost as easily as attenuators can be used to adjust nominal gains.

These products were developed internally to fill a void in the RF industry. It's very difficult to quickly order a fixed slope equalizer to correct an excessive sloped RF path without waiting 10-12 weeks for delivery. Our losses at the high frequency are the lowest available in the industry. We've searched far and wide to find products with the characteristics of our products, but could not find vendors to supply them. So we bit the bullet (many bullets) and worked on these designs ourselves.

We've worked very hard to make these products easily producible. We can deliver these very quickly (typically 2-4 weeks). If you pre-order an equalizer in a certain frequency band, and then let us know what slope you need, we can most likely incorporate the slope and deliver a tested equalizer within 1-2 weeks.

For more information for the current products and designs available, please visit our "Equalizers on Demand" product page.

We hope we can help improve your RF/Microwave system performance with these products! Bob Wood

Hello Everybody

We just delivered our latest product: a multi-channel RF/Microwave Receiver Simulator. This device simulates the RF front end of an ESM (Electronic Support Measures) system. The simulator matched the noise figure, gain and dynamic range of the RF front end. The simulator contained 9 channels of RF bands covering from 10 MHz all the way up to 40 GHz.

Some pictures of the RF Receiver Simulator are shown below. The RF Receiver Simulator is a 3U rack-mounted assembly mounted in a protective roll-away cart for ease of transportability.

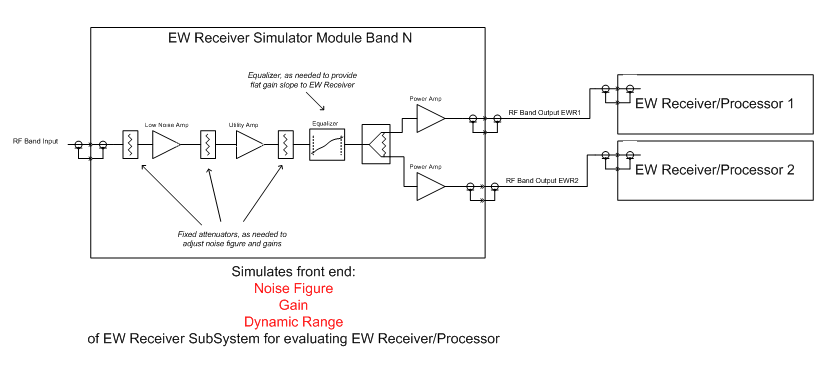

We just delivered an EW Receiver Simulator to one of our customers. The simulator provided the simulated RF and microwave front end performance of an EW (Early Warning) Receiver subsystem. Our simulator allows the EW Receiver/Processor to be evaluated without requiring the actual front end system. The simulator was designed to match the system front end noise figure, gain, and dynamic range. This also represents a new modular and mechanical design for us.

A block diagram of one channel of the EW Receiver Simulator is shown below:

Some pictures of the EW Receiver Simulator are shown below. The box is built to be used as bench-top equipment or as a 3U rack-mount installation. This is the first design of our standard rack-mount chassis, capable of supporting up to 16 plug-in modules (1 inch standard width). Cooling air is pulled from front to back, and the modules are thermally clamped (with Calmark Clamps) to the top and bottom of the chassis.

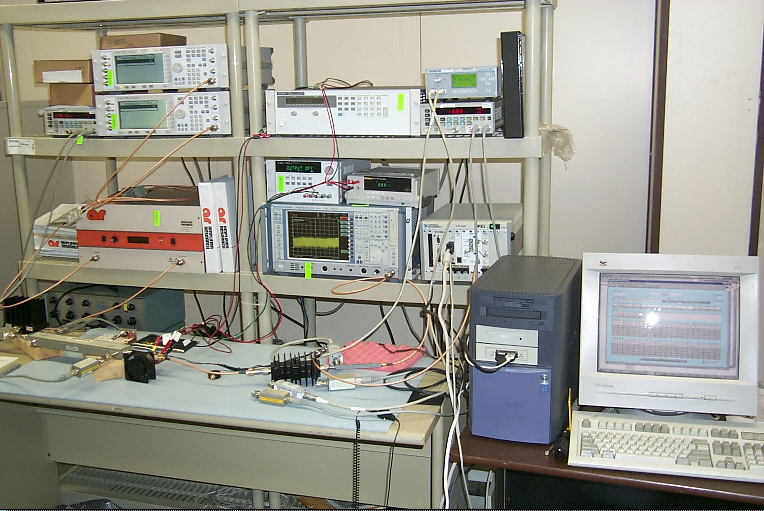

On September 15 2006, R. A. Wood Associates delivered the first two of 15 complete Integrated RF Test Racks. The Integrated RF Test Rack provided a complete solution for complete automated testing of 7 RF/Digital modules. All equipment was controlled through GPIB interfaces. All automated test software was written in National Instruments LabVIEW by R. A. Wood Associates. RFSpecTest was used in "script" mode to perform most of the RF measurements. The rack consisted of:

- 2 Signal Generators (one for RF signals, one for LO signals)

- 1 Spectrum Analyzer (for measuring RF signal amplitudes and frequencies)

- 1 Multimeter (for monitoring resistances and voltages at various points on the modules)

- 3 Power Supplies (for providing DC power to the modules under test)

- A rack mount PC with GPIB and Digital I/O cards, loaded with software for controlling test equipment and reporting test results

- A rack mount interruptible power supply (UPS)

- R. A. Wood Associates Automated RF Test Fixture

- Laser Bar Code Reader (for reading and automatic entry of module serial numbers)

- A 19" Flat Panel Display (mounted on movable monitor arm)

- Keyboard and Mouse in a slide-out ergonomic tray

The full rack was designed to be a comfortable testing environment, as well as easy to maintain. Equipment is easy to remove if needed with minimal interference to other equipment.

More information about the Integrated RF Test Rack is available from this link.

We designed and developed a Computer Automated RF Test Station for one of our customers. The Computer Automated RF Test Station is capable of testing 7 different RF and RF/digital modules, but is flexible enough to test many possible RF modules. The Test Stations were built and tested at R. A. Wood Associates. Computer automated test software was also developed to test the 7 different modules using LabVIEW. RFSpecTest was used in a "scripted" mode to perform all RF tests. More information about the Computer Automated RF Test Station is available at this link.

We delivered a wideband RF/microwave Receiver Simulator to one of our clients on March 1. The simulator was designed to simulate the front end of an RF/Microwave system. Frequency coverage went from HF to SHF Ka Band. The simulator was required to have very low noise figures and very high intercept points/compression points. The unit was delivered in 6 months after order. More information is available at this link location.

R. A. Wood Associates demonstrated our RFSpecTest software product at MTT Symposium in Philadelphia, PA during June 10-12, 2003. See our Press Release for more info.

R. A. Wood Associates introduced their latest computer automated RF test software suite, RFSpecTest, at National Instruments (NI) Week, August 13-16. See Press release. The test software suite is centered around NI's latest RF product, the NI 5660 Spectrum Analyzer. Automated testing for gain, two tone intermodulation products, gain compression, relative measurements, and others was demonstrated for amplifiers, mixers, switches, filters, attenuators, RF integrated circuits and more. Thanks to all who stopped by to see our new product! A picture of our booth and computer automated test setup at NI Week. For an overview of the of RFSpecTest, select this link (1.7 MB pdf file).

Above is our booth at NI Week, where we demonstrated computer automated testing of RF components using the NI 5660 and three RF signal generators, using our RFSpecTest software. The current device being tested is a band pass filter. The RF power meter was used to calibrate the whole setup, including instruments and cable losses, to power meter accuracy.

Upgrade and Repair Services

- One of our clients had received some RF modules that were functionally working, but the performance was not meeting system performance requirements. We analyzed the modules, determined the changes needed to meet system performance requirements, and upgraded the RF modules for our customer. Some of the highlights of this effort:

- New RF components were specified, sent out for quotes, and purchased from vendors

- Improved 1 dB compression points

- Reduced noise power levels

- Improved P-P flatness

- Automated RF test software was developed to perform final acceptance tests

- Acceptance test reports were created and delivered to the customer for each upgraded RF module

- Some of the modules were RF components interconnected with coaxial RF cables

- Some of the modules were surface mount components on microstrip medium

- The system performance was greatly enhanced by these upgraded RF modules

We have developed a computer automated Metal Tester for testing metals using thermo-electric measurements from an Acromag meter, a PC A/D converter board, and LabVIEW software. For more information, go to this page.

Filter Design Study

- We helped a customer analyze a filter specification and provide a filter design that would be producible and come as close to the filter specification as possible. The end result was that the filter requirements were not fully realizable. This enabled the customer to revise their design approach so that a more realizable filter could be utilized, thereby preventing them from going forward with a system design that was not feasible

Computer Automated Test System for LDMOS Wireless RF Power Amplifiers

- We provided an automated RF Test System to provide computer automated testing of LDMOS RF Power Amplifiers. The amplifiers are used in base stations for AMPS, PCS, UMTS systems. Software was developed using National Instruments LabVIEW

- RF Measurements provided at several Output Power Levels

- Gain

- Gain Compression (servoed to X dB gain compression)

- Output Power (servoed to a specified power)

- Intermodulation Products (IMD)

- Adjacent Channel Power (ACP)

- Return Loss

- DC Measurements included:

- IDQ Servo (Adjust Vgg to achieve desired Idd current)

- Idd measurement at RF Output Power

- Ronq

- Ronh

- Gmq

- Gmh

- Other Measurements

- Efficiency

- Power Added Efficiency (PAE)

- For an overview presentation of the LDMOS Automated Test System:

Satellite Communication Phased Array Solid State Transmitter Design

- Spreadsheet modeling of RF signal paths and RF path parameters

- Developed specifications for RF components

- Performed requirements analysis and specification flow down

- Developed a "B2 Level" specification for the microwave assembly

Cable TV System Model to Predict Linear and Nonlinear Performance from Headend to the Home

- We developed a CATV system model to predict performance from the CATV Headend to the Home

- Performance predictions included:

- Carrier to Noise (C/N)

- Composite Triple Beat (CTB)

- Composite Second Order High (CSOhigh)

- Composite Second Order Low (CSOlow)

- Amplitude Levels vs Frequency

- Slope

- Channel Plans Analyzed:

- 79 Channel

- 95 Channel

- 112 Channel

- 125 Channel

- Other Parameters...

- An example spreadsheet printout (Adobe Acrobat pdf format) is shown here, showing 6 cable spans and amplifiers

- Individual Components and their associated parameters were created and added to a component database. The database tracked over 900 RF component parameter fields for various components used in the cable TV industry. The initial database contained over 800 components, with capability of adding thousands more components. Data could be imported into the database from files created by other programs (S2P files, for example).

MetalTest Software

A software program was developed using LabVIEW, a graphical programming language from National Instruments. The program runs on a PC and is connected to an Acromag Metal Tester using a PC Data Acquisition board. The program compares the readings gathered from the Metal Tester to readings in a database for various alloys. The program then gave a readout of what metal alloy most closely coincided with the metal being tested. The program also provided probability levels (T-Test) to show confidences against the various other possible alloys in the database. The MetalTest System is currently being used to recycle aircraft engine machining scrap and is helping the company earn hundreds of thousands of dollars in metal reclamation sales.

EW System Analysis and Support

- We helped a customer with system design, analysis and support for a naval surface ship EW system over a 3 1/2 year period. Some of the key points of this effort:

- Developed specifications for EW subsystems, WRA's, SRA's, and RF components

- Developed analysis programs to predict system performance and specify from subsystems down to components

- Helped investigate new technologies for various subsystems, such as RF delay lines, RF channelizers, etc.

- Attended vendor design reviews and meetings to support the customer

Engineering Consulting Examples: IF Receiver/Digitizer

Software was developed to retrieve the binary data from a IF Receiver/Digitizer board. The board design utilized a 10 MHz A/D converter to sample the IF signal. A Logic Analyzer attached to the board captured the digital data from the IF Receiver/Digitizer board. The computer used an IEEE-488 interface to connect to the Logic Analyzer and retrieve the values. After the binary data was retrieved, converted, and stored in an array, the data could be graphed and analyzed. The arrays were converted to a series of voltage values of the incoming signal. The voltages were plotted and then recorded. The data was then used in signal frequency and noise analysis. The Fast Fourier Tranform was used to determine the spectral content of the sampled signals. The FFT of the digital signal could then be compared to the Power Spectrum Analyzer data of the analog signal. The software was developed using National Instruments LabVIEW graphical programming language. The measured data could be stored to a data file to record that particular test.

Panel showing A/D Noise Floor Measurement:

Panel showing A/D Measurement of 4 MHz Signal:

Panel showing A/D Measurement of 17 MHz Signal:

Cryogenic Cooled RF Amplifier Development for PCS Application

- We helped a company involved in Cryogenic packaging to design, verify and test a cryogenic cooled LNA package. We used LabVIEW software to develop a complete computer automated test station, providing the following measurements controlled by LabVIEW via GPIB interfaces:

- Full 2-Port S-Parameters

- Noise Figure vs. Frequency

- 1 dB Output Compression Point vs Frequency

- Two Tone Third Order Output Intercept Point vs Frequency

- The test setup was designed so that a lot of detailed testing could be completed in a very short time while the device was in a vacuum and being cooled with liquid Nitrogen. The test equipment being controlled included:

- HP Network Analyzer

- HP Noise Figure Meter

- HP Power Meter

- HP Signal Generator

- HP Spectrum Analyzer

- All measured data was stored electronically in electronic format for importing into spreadsheet programs for further analysis and plotting of results.....

High Speed Synthesizer for Medical Monitoring Equipment

The figure above is a simplified block diagram of a high speed synthesizer developed by R. A. Wood Associates for a medical application. Some of the preliminary specifications are shown below:

- Output RF Power:

- The output RF power in to 50 ohm load shall be 3 Watts minimum

- Output VSWR

- 1.7:1, 50 Ohm reference impedance.

- Frequency Source Requirements

- The RF source shall provide 2 selectable frequencies (Frequency 1 and Frequency 2). The frequencies are selected based on the logic level applied to the Freq Change Strobe. When the Freq Change Strobe is logic 0, the output frequency shall be at Frequency 1. When the Freq Change Strobe is Logic 1, the output frequency shall be at Frequency 2.

- Frequency Range

- The output frequency range shall be 80 to 120 MHz.

- Frequency Resolution

- The frequency resolution of the source shall be less than 1 KHz

- Spurious (In-band)

- The maximum level of spurious signals within the frequency range of 60 MHz to 160 MHz shall be -30 dBc relative to the RF output signal level.

- Harmonics and out of Band Spurious

- he maximum level of harmonics and spurious signals outside the frequency range of 60 MHz to 160 MHz shall be -20 dBc.

- Digital Interface:

- Serial Interface, 2 wire, Clock and Serial Data

- Power Level Control

- Analog Input for Power Control: 0 to 10 Volts, approximately linear, to adjust RF power from 1 to 3 Watt

- Frequency Switching Time:

- Less than 5 uSec (actual performance is less than 10 nSec)

RF Wireless Link for 915 MHz ISM Band

- We provided a quick turnaround prototype design for a customer. The project involved designing a wireless link for sending and receiving digital data. The transmitter used FSK modulation at 915 MHz to send the digital information. The transmit power levels were restricted to less than 1 mW. The receiver provided front end filtering, low noise amplification, and demodulation of the FSK signals to digital information. Most of the components used were RF integrated circuits from RF Micro-Devices. The link was field tested also.

Software Controlled Laser Power Meter Interface

- Software was developed to provide a computer-controlled interface to a Universal Radiometer. The Universal Radiometer is a piece of test equipment used to measure laser power. The device was controlled by a PC serial port. The software was developed using National Instruments LabVIEW graphical programming language.

- All instrument controls are sent from the screen display through the PC serial port to the test equipment.

- Data from the test equipment is sent via the PC serial port to the computer and analyzed and displayed on the screen display.

- Measured data can be stored to an external file in Microsoft Excel or other spreadsheet compatible format.

- Measurement statistics are calculated and displayed in real time

RF System Design for F-22 Electronic Warfare (EW) System

- RF System Performance Predictions and Specification Development

- Develop RF system analysis models to specify and predict RF system performance

Noise Figure Computer Automated Test

- The Need:

- A customer was using an existing computer automated test software to provide noise figure measurements for RF amplifiers. The program was written in HP BASIC, and the software was run on an older HP computer. The software was antiquated and not user-friendly, the computer was aging and unreliable (used 5 1/4 inch floppies, etc). The test setup was limited to about 750 MHz in frequency coverage.

- The amplifiers were used for CATV distribution amplifiers, and the test setup was used by Incoming Inspection and Test to verify specification compliance.

- The Customer wanted to upgrade the software to HT BASIC, replace the computer with a newer PC compatible computer, provide a better, more user-friendly interface, allow different devices to be tested to different specifications, and increase the measurement capability to provide accurate measurements up to 1000 MHz.

- The Solution:

- R. A. Wood Associates transferred the existing software over to HT BASIC, which was then developed on a PC compatible computer. The software was completely re-written to provide a menu-based test setup, where the user could select parameters for calibration, test, and set up specification limits. Once the test parameters were set up, the test person could just insert the devices into a "quick connect" fixture and push the "TEST" button for quick verification.

- A user-friendly test interface was designed and implemented.

- The test procedure was revised using improved test and calibration techniques to provide accurate noise figure and gain measurements for frequencies up to 1500 MHz.

- Other Points to Make:

- The software was developed at R. A. Wood Associates, and installed and verified at the customer's location.

- User-defined test and calibration frequencies allowed the operator to greatly reduce test time

- which helped save money for the customer.

- The software was designed to be user-friendly:

- A menu based structure was designed.

- New test parameters could be easily be added.

- Press "RETURN" for default parameters saved re-typing current parameters.

- The software was structured for minimal maintenance and easy upgrades.

- A complete user documentation package was provided to the customer for training purposes.

- The test setup used HPIB interfacing and HP 8970A Noise Figure Meter.

- The setup was designed to test devices in a 75-Ohm environment.

- For the entire effort, we kept the customer's needs in mind as a primary objective.

HP BASIC Software to Provide Test Interface to Micro-controller

HP BASIC Program for controlling an on-board micro-controller through a PC serial port interface. This was to be used in an automated test environment.

Subcontract Specification Development

A commercial manufacturer needed to develop a subcontract specification for an integrated RF assembly which they wanted to send out for quotations, and subcontract the design and development services. R. A. Wood Associates analyzed the requirements for the device based on its "system" application, and developed a 25 page specification for the device. All this occurred to meet a rush deadline in about 3 weeks time. More info to be provided...

Wireless Components Research

Provide research and quotes for wireless components including low noise RF amplifiers, ceramic filters, base station duplexers in the cellular frequency bands.